What are the uses of PCB aluminum substrates?

2022-09-23

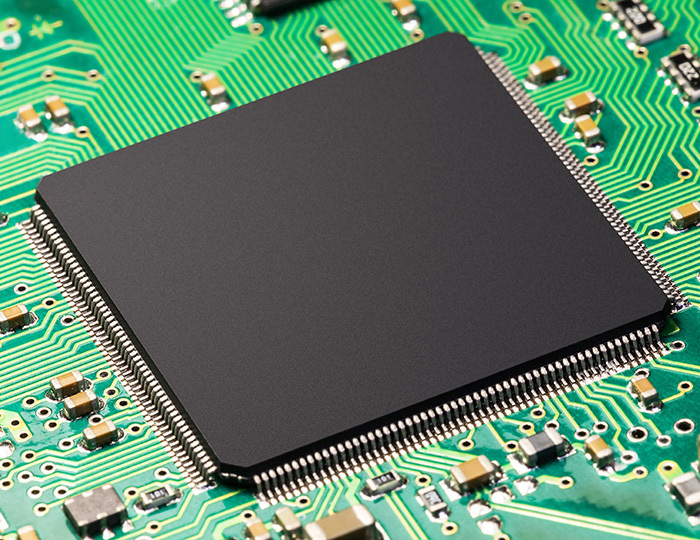

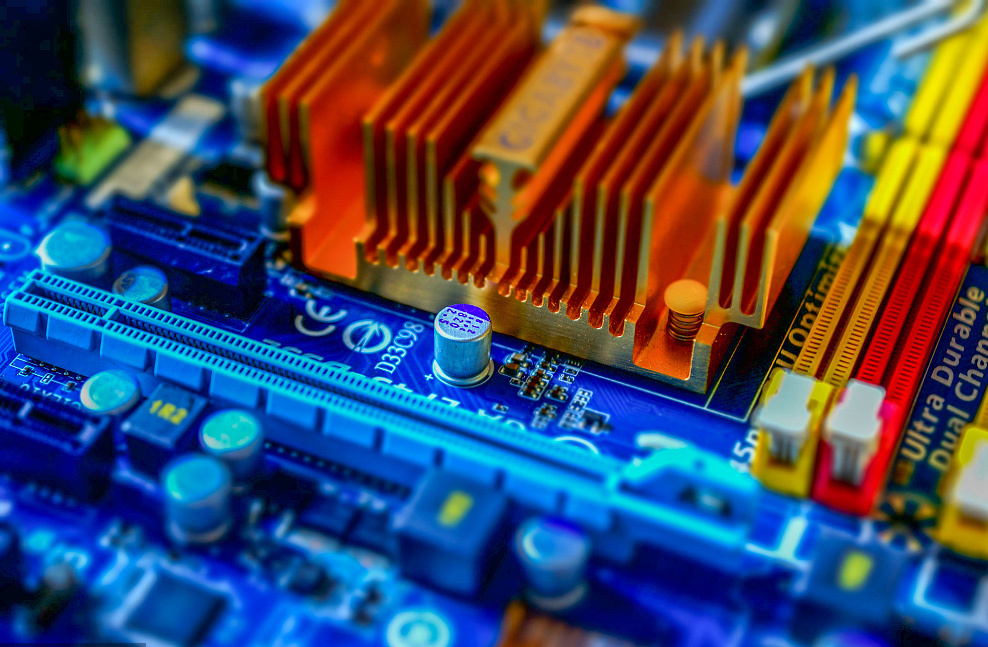

Aluminum substrate is a metal copper clad laminate with good heat dissipation, which is the basic material of high-power power electronic circuit structure technology and interconnection technology.

Aluminum substrate is a metal copper clad laminate with good heat dissipation, which is the basic material of high-power power electronic circuit structure technology and interconnection technology. For PCB proofing, the aluminum substrate generally includes a three-layer structure, which is a circuit (copper foil), an insulating layer and a metal bottom plate; a double-sided board, a structural circuit layer, an insulating and thermally conductive layer, an aluminum base, an insulating and thermally conductive layer, and a circuit layer. There is another double-sided aluminum substrate, which is made of glass fiber board and aluminum base. The bottom layer is aluminum base, the core board is aluminum, and the top and bottom are routed.

When used for PCB proofing, what is the use of aluminum substrate?

1. Audio equipment: input and output amplification, balance amplification, audio amplification, preamplifier, power amplifier, etc.

2. Power supply device: switching regulator, DC/AC converter, SW regulation, etc.

3. Communication electronic equipment: high-frequency booster, filter electrical appliances, signal transmission circuit.

4. OA equipment: motor drive, etc.

5. Automobile: electronic governor, ignition device, power controller, etc.

6. Computer: CPU board, floppy drive, power supply device, etc.

7. Power module: inverter, solid state relay, rectifier bridge, etc.

8. Lighting: PCB proofing, aluminum substrates for LED lights have also begun to be applied on a large scale.

Key words:

Previous Page: